Johns Manville

Johns Manville Roof Products

Johns Manville was Founded in 1858 by Henry Ward Johns who Partnered with Charles B. Manville in 1886 (Johns Manville Corporation) Specializing in Hot Tar Roofing Shingles, Pipe Insulation and a variety of Industrial products considered Highly Innovative for the era. In 2001 Johns Manville became a subsidiary of Berkshire Hathaway Inc. Now based in Colorado, Johns Manville Roofing Materials are known for an Innovative Approach to Traditional Roofing Systems. From Single-Ply and Asphalt Systems to Unique Hybrid Roofing Systems. Johns Manville produces Quality Materials that Withstand a Variety of Elements and are Backed By a Top-Tier Warranty. Concentrating on New Innovative Products to Reduce Energy Costs.

Single-Ply Roofing Materials

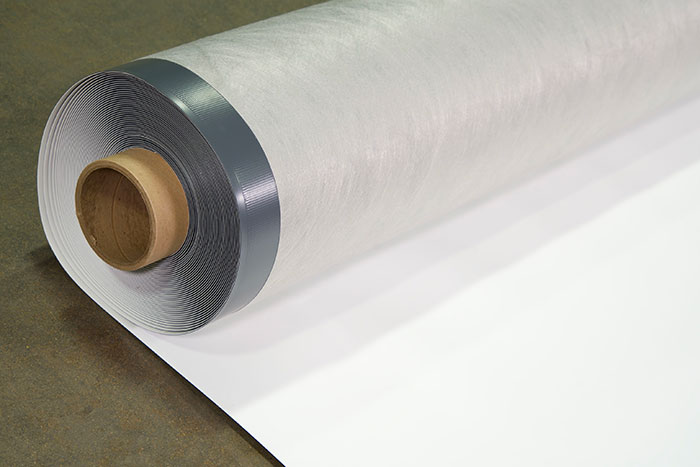

TPO

Johns Manville TPO Membranes are Manufactured with a Reinforced Polyester Fabric Combined with a UV Resistant TPO Formulation. These TPO Systems offer Extreme Flexibility, Pliability, and are Easily Welded.

JM TPO Roofing Membrane

Benefits:

- Exceeds ASTM D 6878 requirements

- Weld Abilities throughout Various Temperatures leading to a More Flexible Sheet.

- Variety of Gauges to work with

- Durability due to a Reinforced Fabric scrim layer

- Advanced TPO Formula

JM TPO SA – 60 mil

Benefits:

- Meets ASTM D 6878 requirements

- Wide Weld Window

- Top Ply Layer over Reinforced Fabric scrim layer

- Advanced TPO Formula which is Weather, Ozone and UV Resistant

JM TPO Fleece Backed Roofing Membrane

Benefits:

- Meets ASTM D 6878 requirements

- Durability due to Flexible Polyester Fleece Backing

- Wide Melt Window

- Top Ply Layer over Reinforced Fabric scrim layer

- Advanced TPO Formula which is Weather, Ozone and UV Resistant

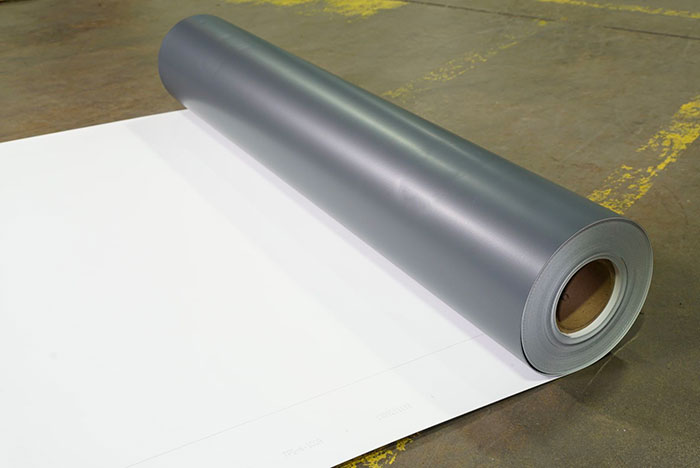

PVC

Johns Manville Manufactures Three Types of PVC Membranes to Ensure you find the Optimal Membrane for your Commercial Roofing System and Industrial Roofing System. These Membranes are Manufactured to be Resilient, Flexible, and UV Reflective Ensuring a Long Lasting Roof that Stands Up to a Multitude of Elements

JM PVC with Dow Elvaloy KEE Polymer

Johns Manville PVC uses Dow Elvaloy KEE & JM PVC SD M PVC with Dow Elvaloy® KEE and JM PVC SD Thermoplastic Membranes are Engineered with a UV Resistant Polyvinyl Chloride. Using Polyester Reinforcement Fabric results in a System that can be Adhered or Mechanically Attached. PVC Roofing Membranes are Flexible, Tough, Chemical and Weather Resistant resulting in a Low Maintenance Roofing Membrane with Excellent Longevity.

Benefits:

- Aramid Fiber Woven into Fastening Side of the Membrane

- Non Wicking Polyester Reinforced scrim layer Adding Durability and Strength. The Non Wicking Edges Do Not Require a Sealant.

- Chemical Resistance to AC Coolants, Oils and Fuel.

- Energy Efficient White, Grey ES, & Sandstone ES provide Superior UV Reflectivity.

PVC mil/MIN with Dow Elvaloy KEE Polymer

Heat Weldable Membrane

Benefits:

- ASTM D 4434, Type III requirements met.

- Innovative Solid Phase Polymer Formula Using Dow Elvaloy KEE (Ketone Ethylene Ester) Polymer allowing for Added Flexibility, Low Maintenance and Roof Life Longevity.

- Minimum thickness of 60 & 72 mils

- Aramid Fiber Reinforced Edge – Patented

- Non Wicking Polyester Reinforced scrim layer Adding Durability and Strength. The Non Wicking Edges Do Not Require a Sealant.

- Chemical Resistance to AC Coolants, Oils and Fuel.

- Energy Efficient UV Reflecting White Membrane.

JM PVC FB with Dow Elvaloy KEE Polymer

Thermoplastic Membrane that Combines a Spunbond Fleece resulting in a Light, Flexible, Durable Membrane that can be Mechanically Fastened to a Variety of Substrates.

Benefits:

- ASTM D 4434, Type III requirements met.

- Aramid Fiber Reinforced Edge – Patented

- Spunbond Interlocking 3.8 oz. Multilayer Polyester Fleece Back Mat – Durable, Flexible and Light

- Non Wicking Polyester Reinforced scrim layer Adding Durability and Strength. The Non Wicking Edges Do Not Require a sealant.

- Chemical Resistance to AC Coolants, Oils and Fuel.

JM PVC SD Plus

Heat Weldable Membrane is Available in Increased Thickness of 50, 60, and 80 mil.

Benefits:

- ASTM D 4434, Type III requirements met.

- Non Wicking Polyester Reinforced scrim layer Adding Durability and Strength. The Non Wicking Edges Do Not Require a Sealant.

- Chemical Resistance to AC Coolants, Oils and Fuel.

EPDM

(ethylene propylene diene monomer)

The Johns Manville State-Of-The-Art EPDM manufacturing facility is equipped to press roll EPDM sheets rather than traditional calendering. JM EPDM Membrane is also manufactured to be Thicker with a More Uniform Surface Finish for a Stronger Bond in the Installation Process.

JM EPDM NR TPO Roofing Membrane

Non Reinforced, EPDM Membranes

Benefits:

- Cured 45, 60, & 90 mil

- Fully Press Rolled Reduces Air Pockets – Consistently Thick Smooth Sheets.

- The Vulcanization Technique results in a Solid Cross Linked 2 Layer Membrane.

- Performs in Intense Climates and Stands up to Movement.

- Excellent UV, Ozone and Weather Resistant

JM EPDM R

Reinforced Cured EPDM

Benefits:

- Reinforced with a Rugged 1000+ Denier Polyester Fabric.

- Fully Press Rolled Reduces Air Pockets – Consistently Thick Smooth Sheets.

- Vulcanization Technique results in a Solid, Repetitive Waterproof Membrane.

- Performs in Intense Climates and Stands up to Movement.

- Excellent UV, Ozone and Weather Resistant

- ASTM D 4434 Type II requirements met

JM EPDM NR FIT Systems

Cured Non Reinforced Membrane with Manufactured Inseam Tape.

Benefits:

- Manufactured Inseam Tape – High Quality assuring a Savings in Labor Costs in Comparison to Job Site Fabricated Seams.

- Reinforced with Rugged 1,000+ Denier Polyester Fabric.

- Fully Press Rolled Reduces Air Pockets – Consistently Thick Smooth Sheets.

- The Vulcanization Technique results in a Solid Cross Linked 2 Layer Membrane.

- Performs in Intense Climates and Stands up to Movement.

- Excellent UV, Ozone and Weather Resistant

- R FIT 60 mil and R FIT 75 mil

- ASTM D 4637 Type I requirements met.

Asphalt Roofing Systems

Built-Up System, Modified Bitumen System, or a Hybrid of Both. For Over Three Decades Johns Manville has the Asphalt Roofing Material necessary to Provide Extraordinary Protection for your Commercial Building or Manufacturing Facility. JM products are Engineered with Mix of Polymers Combined with Selected Grades of Refined Asphalt Creating Products with Exceptional Flexibility & Strength.

SBS

- Johns Manville SBS Roofing Systems offer Superior Modified Bitumen Designed Specifically for Flexibility.

- Standing up to the Most Severe Environments.

- SBS is Reinforced with Glass, Composite, and Polyester, and is Extremely Customizable.

- SBS Roofing Systems can be Heat-Welded, Hot-Applied, Cold-Applied, Mechanically Fastened and Self-Adhered.

- Appropriate for Low-Slope Commercial Roofing Systems

The Alpine Roofing Construction JM SBS Experts will Assist you in choosing the Correct SBS Roofing System for your Commercial Roofing, Industrial Roofing or Manufacturing Facility Roofing Project.

APP

- Johns Manville APP Roofing Systems Combine Premium Asphalt with Glass Fiber or Nonwoven Polyester. This Reinforced Structure Maximizes Strength, Affordability and Weatherability.

- JM APP Roofing Membranes are Applied with Ease with Minimized Hooking Resulting in Straighter Lines, a Smoother Appearance and Increased Protection.

- Multiple Color Options are Available.

The Alpine Roofing Construction JM APP Experts will Assist you in choosing the Correct APP Roofing System for your Commercial Roofing, Industrial Roofing or Manufacturing Facility Roofing Project.

BUR

Johns Manville Pioneered BUR Roofing Systems in the US Over 160 Years ago. Very few Roofing Manufacturers claim to have applied practically One Billion ft of BUR that are Under Full Guarantee Today.

- The Built-Up Membrane Layers of Bitumen and Felt Provide Maximum Durability and Lifespan.

- The JM Weather and Waterproof Membrane offers Exceptional Protection that Does Not Depreciate.

Liquid Applied Commercial Roofing Systems

Johns Manville Liquid Applied Roofing Systems Conform to Unique or Difficult Roofing Designs.These Water and Weather Resistant Membranes are Applied with Ease in Confined Spaces, Multiple Penetrations or Controlled Heat Welding and Hot Mop Situations

Contact Alpine Roofing Construction JM Liquid Applied Commercial Roofing System product Specialist for your Appropriate Commercial Roofing, Industrial Roofing and Manufacturing Roofing System.